Readings around the furnace suggest that something is wrong with the fresh air intake. The duct is just a flexible hose, so I thought it might be pinched somewhere.

I discovered that the fresh air duct was not really attached to the outside of the house. Instead, it was simply resting in front of the rim joist in front of the exterior vent. The vent collar was missing, so there was nothing for the duct to attach to. That’s like breathing through a snorkel that’s only touching your lips. What’s more, the vent only lined up with half of the hole in the rim joist. That’s like breathing with only one nostril. At minimum, I’ll have to replace the rusty exterior intake vent in order to fix this.

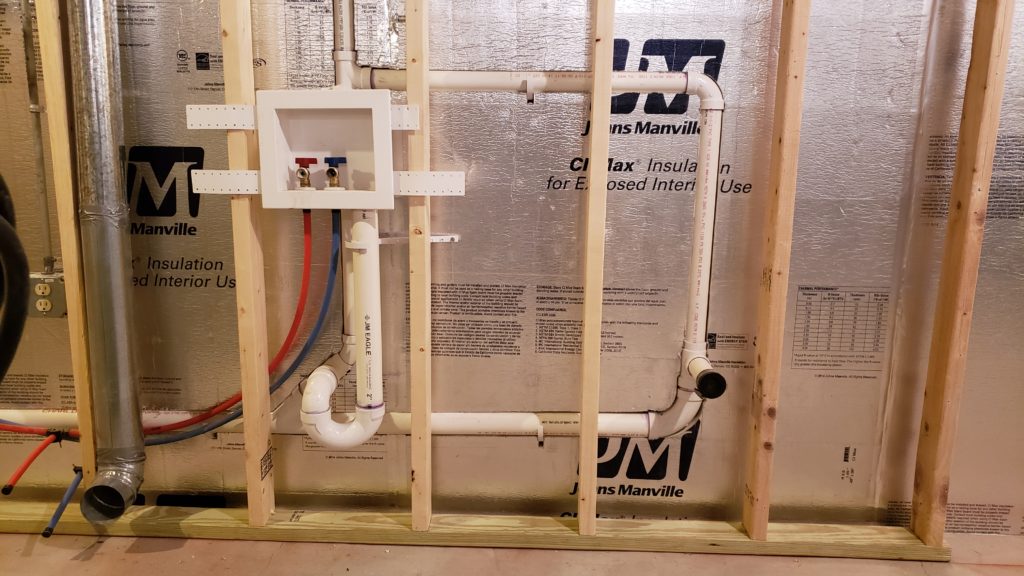

My plumber also returns to move my laundry drain pipes to their final location. He only moves the drains, so he’ll have to come back and do the water pipes later. I ask him to leave some of the venting disconnected while I finish insulating the basement wall.