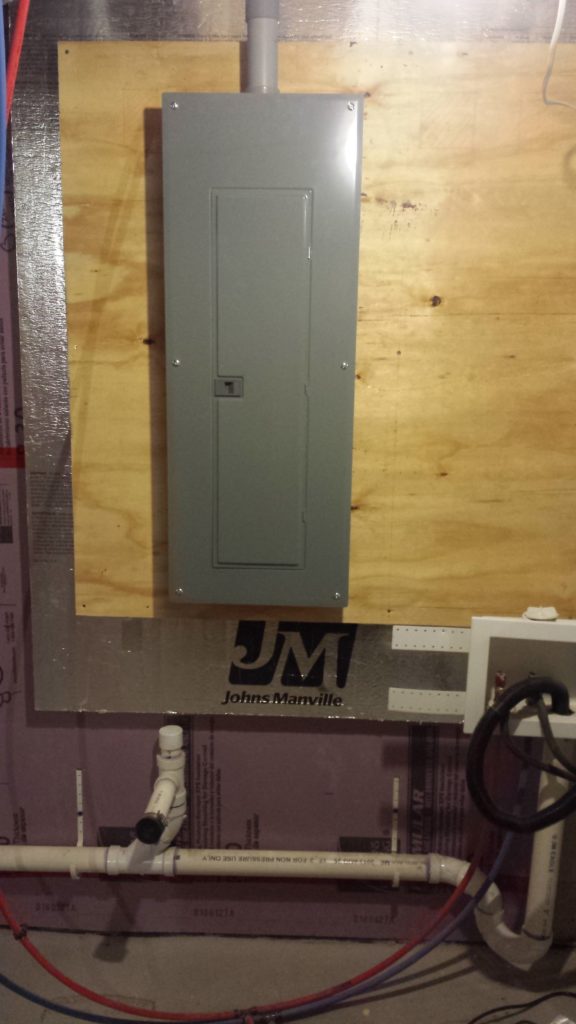

Today my electrician disappointed me. I hired him to move my electrical service panel, which he did. As for all of the other electrical problems in the house, he simply refused to fix them. He said they’re too hard to find, and not worth his time.

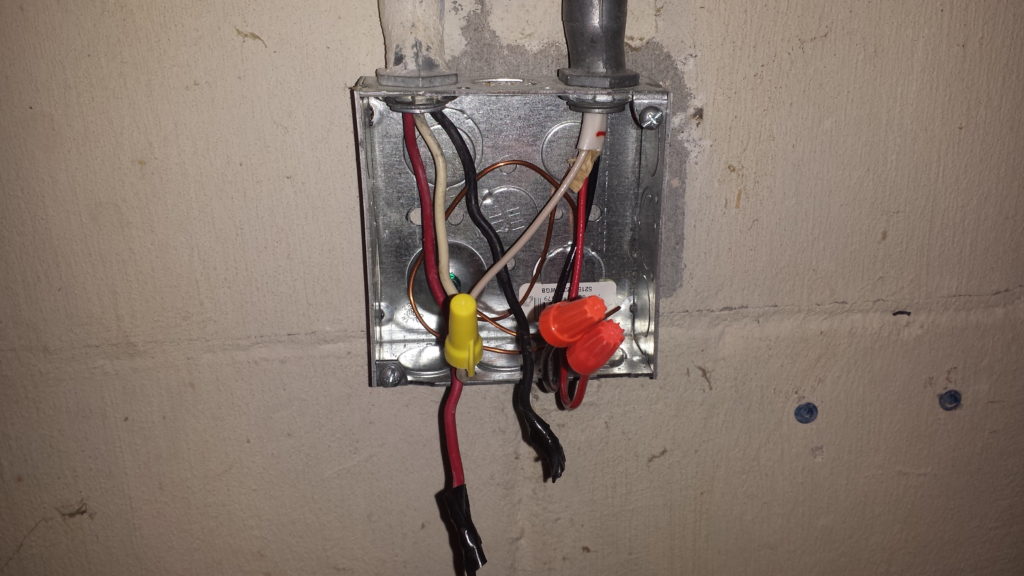

One such problem has to do with a circuit that runs through this junction box. It’s huge circuit that powers most of the house including lights, outlets, the refrigerator, the washing machine, the garage door opener, and more. Somehow, both ends of the circuit are on separate breakers. Removing the connection at this junction box doesn’t break the circuit. Instead, it causes a “free neutral”. When that happens, the lights in the house blink on and off. You can’t make this stuff up.

I asked him what it would take to fix the problem. He wouldn’t give me a bid, saying the problem could be hidden anywhere, like in the attic. I tried to reason with him, saying that the entire basement is exposed, and the attic has very safe lighting and rat runs. He simply said “I don’t do attics” and wouldn’t even look.

Unfortunately, untangling this mess means I’m going to have to hire another electrician, or find a way to do the job myself.